Freight Charges will apply. Please call 214-342-9290 to get a freight quote.

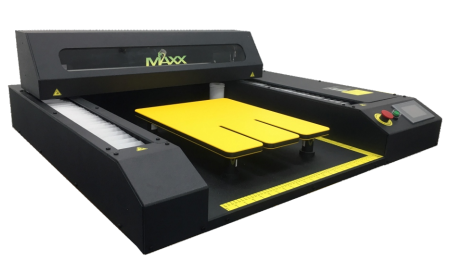

The ALL-New Viper MAXX Pretreatment Machine is the newest innovative pretreatment machine from i-Group Technologies that is destined to change the DTG industry once again. The MAXX takes all of the best innovations and lessons learned from the past 10 years of producing the world’s leading pretreatment machines and put them together to create the ULTIMATE spray application process for DTG.

The MAXX is so feature rich that it allows for a perfectly even application of pretreatment every time, with every pretreatment on the market. Complete user control over all of the variables allows for precise spray application in only the areas required. No more pretreating the entire shirt for just a left chest DTG print. With 99.9% efficiency and no spraying off the shirt you can only pretreat the areas intended with the touch of a button.

Features

- SPRAY SIZE - Up to 19″ x 24″ Spray Area (+/-)

- CONTROL - Set All Parameters for Spraying

- SPRAYING - 4 User Defined Spray Values

- SPRAY AREA - 30 User Defined Pattern

- EZ LOAD - No Drawers To Open/Close

- EFFICIENT - 99%+ Efficient / Minimal Overspray

- BarCodes - BarCode Reading Capable

PRODUCTION & REDUNDANCY IN PRETREATING

When you are running a higher volume Direct To Garment printing facility, you are printing a LOT of shirts every day. You need to ensure that you are up and running while controlling all of the variables. You don't want to waste pretreatment or have downtime on your DTG pretreating department that can shut down your ENTIRE DTG printing facility.

The MAXX is truly a production oriented pretreatment machine with production rates of 90-135 shirts per hour on a single Viper MAXX. In addition, you can utilize the BUILT-IN bar code scanning feature to implement customized pretreatment areas and application amounts for each style of shirt and individual customer order. This enables you to more efficiently apply pretreatment, use less fluid, and increase productivity while maintaining up-time.

If a single point pretreatment application is running your entire DTG printing operation, what happens if (when) there are issues with the pretreatment machine? Your entire production shuts down. Utilizing multiple Viper MAXX pretreatment machines means if you ever do have an issue, you can continue pretreating and printing DTG shirts. Efficiency, versatility, and productivity is what the Viper MAXX is all about. Making DTG pretreating easier - on every shirt.

EASILY FIND THE CORRECT AMOUNT OF PRETREATMENT TO APPLY

One of the hardest things in DTG printing is determining the correct amount of pretreatment to use on each garment. This will vary based on the weight of the shirt, color, density, quality, manufacturing processes and more. So, how do you determine how much pretreatment to apply to get the BEST possible DTG print?

i-Group Technologies has always been a leader in the DTG industry and to continue in that tradition we have built into the Viper MAXX the ability to do a DTG STEP TEST. What is the STEP TEST?

A STEP TEST allows the machine to apply 6 different "zones" of pretreatment on a single shirt that slightly increases in PT application in each zone. So, instead of pretreating multiple shirts and printing them to find the correct amount of pretreatment, the Viper MAXX does this automatically for you. All you need to do is run the STEP TEST and then cure your PT, print a white box across the entire test area and read the results.