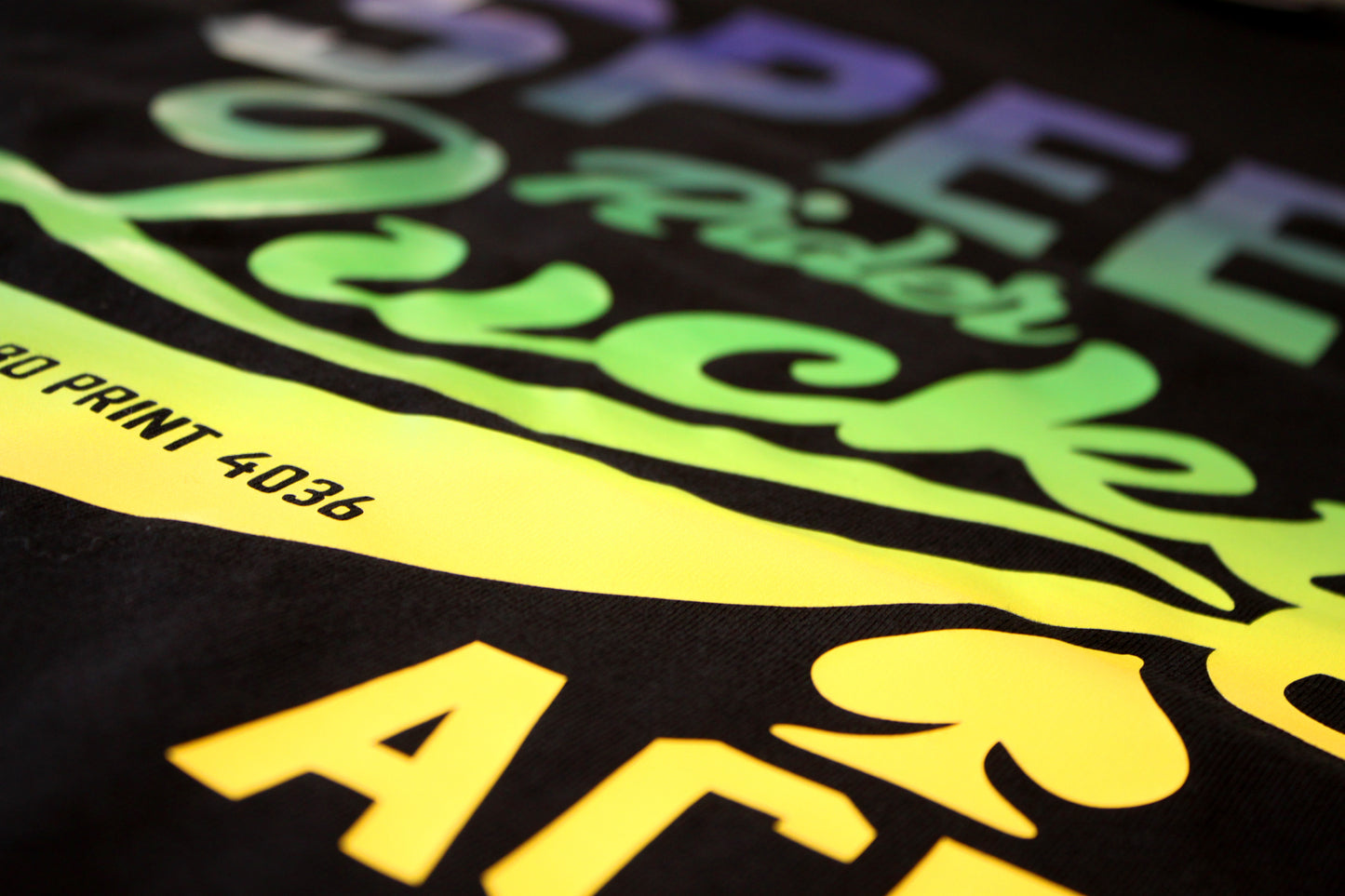

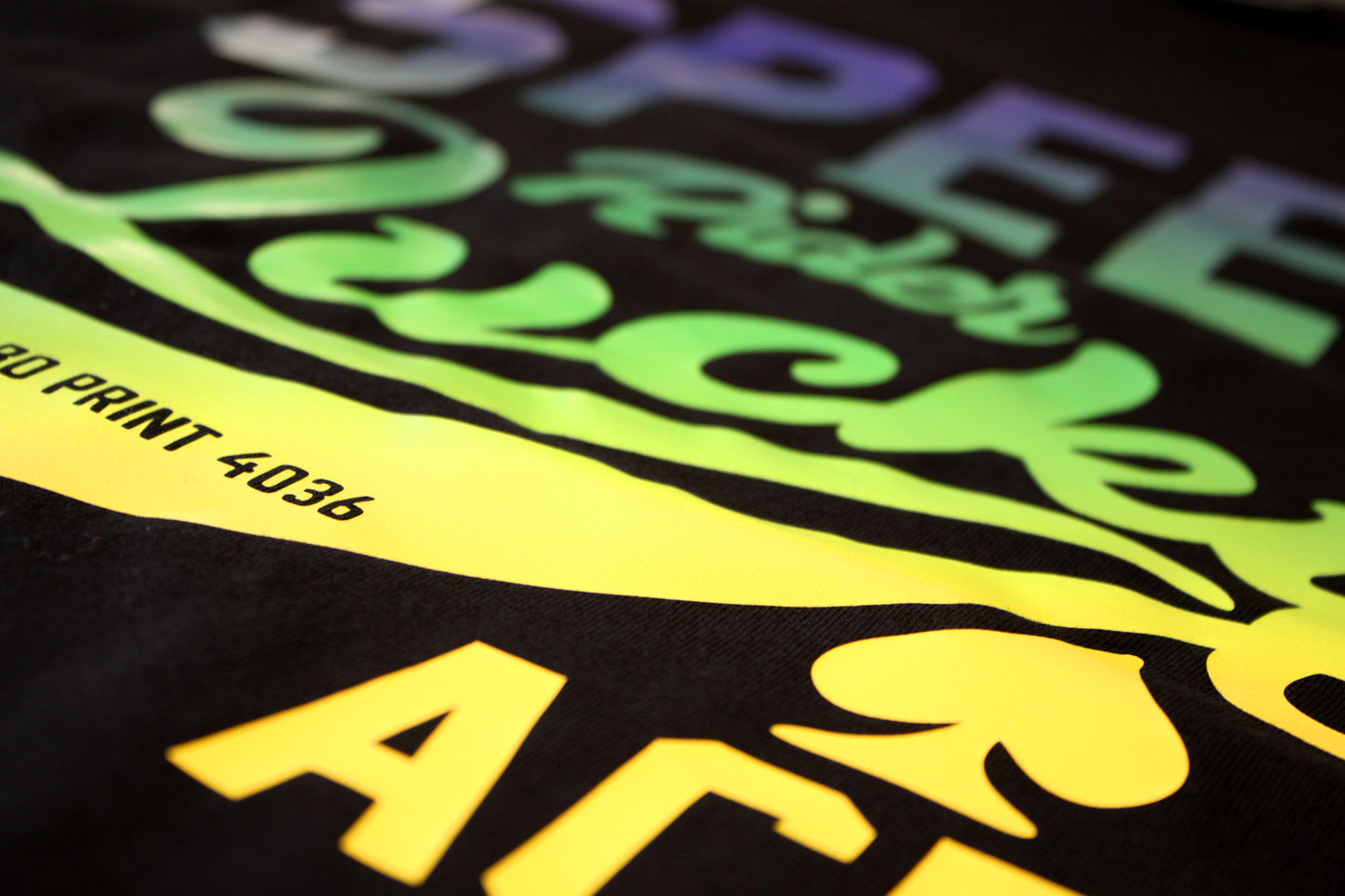

TURBO PRINT 4036 MATTE is a heat-sealable, printable PU textile transfer vinyl (opaque white, 100 µm) suitable for light and dark textiles. TURBO PRINT 4036 MATTE offers a high print resolution with a matt finish and has a pleasant soft textile touch. Due to a special top coat, the vinyl offers an excellent washing-resistance. The transfer vinyl is used for motifs and logos on sport, leisure and work wear, letting for T-shirts, sport bags and other promotional items.

TURBO PRINT 4036 MATTE is suitable for transfer to textiles like cotton, polyester, uncoated nylon, mixtures of polyester/cotton and polyester/ acrylic. For application to Nylon that is treated with any kind of coating, please test for suitability.

TURBO PRINT 4036 MATTE is compatible with all current printers using ECO-solvent, solvent and latex inks. Due to a newly developed, self-adhesive PET vinyl liner, even very small letters and motifs can be easily cut by all current CAD/CAM plotters after the printing process. We recommend using POLI-TACK 854 as a transfer tape and as a protection cover during the heat transfer. The PET liner should be removed warm.

The raw materials are ecologically inert, do not contain PVC, plasticizers or heavy metals, in accordance with OEKO-TEX® Standard 100 category I (CPSIA compliant

COMPATIBLE INKS: ECO-Solvent, Solvent and Latex inks

LINER: PET-film, 100 µm, self-adhesive

RECOMMENDED APPLICATION TAPE: POLI-TACK 853, POLI-TACK 854

APPLICATION INSTRUCTIONS

- Transfer Film: Polyurethane, cast

- Thickness [mm]: 0,095 +/- 5 %

- Liner: PET-film, self-adhesive

- Peel: Peel Warm

- Materials: Cotton, Polyester, Poly-blends, Uncoated Nylon, Mixtures of polyester/cotton

- Wash instructions: Inside out, Tumble dry, low heat

Transfer Conditions

- Pressure: Medium pressure

- Temperature / Time:

- 265° F, 5 sec.

- 300° F, 4 sec.

- 320° F, 3 sec.

For NYLON:

Pressure: Low pressure

Temperature / Time: 300° F,

- Pre Heat 5 sec.

- Apply to Nylon 5 sec.

- Remove PET liner, cover transfer with

silicon paper & apply for further 10 sec.

Technical Data

Transfer Film

Polyurethane, cast

Adhesive

Polyurethane-hotmelt

Thickness [mm]

0,10 +/- 5 %

Liner

PET-film, self-adhesive

Transfer Conditions

Pressure

medium pressure

Temperature / Time

265° F, 5 sec. / 300° F, 4 sec. / 320° F, 3 sec.

NYLON

Pressure

2,0 bar [low pressure]

Temperature / Time

- 300° F,

- Pre Heat 5 sec.

- Apply to Nylon 5 sec.

- Remove PET liner, cover transfer with silicon paper & apply for further 10 sec.

Please consider to adjust the application time when using highly structured cotton or cotton mixture fabrics.

Wash Resistance / Printing

Wash resistance

- 140° F

- Only colour or mild detergent. Wash textiles inside out. Suitable for tumble drying (commercial tumble dryer up to 212° F).

Printing

True sided